Tree Supports and New Printing Profiles in Major Z-SUITE Update

Summary

- Z-SUITE 2.15.0 has been released and is ready for download.

- This major release has been preceded by an extensive beta testing program.

- Key features include new types of support for the Inkspire Inventure, and M300 Dual, as well as new or improved printing profiles for a wide range of materials.

The release of Z-SUITE 2.15.0 has been preceded by the most extensive open beta testing program in Zortrax history. Reaching out to our vibrant 3D printing community for suggestions and feedback resulted in the most user-focused and thoroughly tested Z-SUITE we have ever made. Here’s the overview of what it brings to the table.

Fine-Tuned Printing Profiles

Printing profiles are sets of predefined printing parameters defined for each material supported by a 3D printer. A printing profile determines crucial things like extrusion and build platform temperatures, the speed with which a printing head moves, or the rate at which the material flows through the extruder. Getting all those things right takes lots of time and effort invested in testing but is essential to successful, high-quality prints.

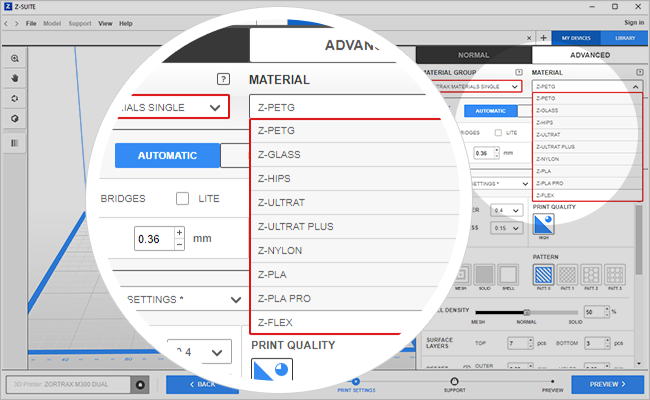

Z-SUITE 2.15.0 comes with a number of new printing profiles for single extrusion mode in Zortrax Inventure and M300 Dual.

Z-SUITE 2.15.0 comes with 15 either significantly improved or entirely new printing profiles for Zortrax M300 Dual, and Zortrax Inventure, which is the highest number of new presets introduced in Z-SUITE since more than a year. This has been made possible by a huge number of our community beta-testers who helped us pinpoint the most optimal printing settings for each material. You can find all the new profiles in the following table.

| Single extrusion | Dual extrusion |

|

|

Improved or entirely new printing profiles have been implemented for dual extrusion 3D printing.

What makes this even more impressive is that, in some cases, we had to define different printing settings not only for the material itself but also for specific layer heights with which it is printed. For example, new printing profiles for single-extrusion Z-FLEX include settings optimized for 0.15, 0.20, and 0.30 mm layer heights.

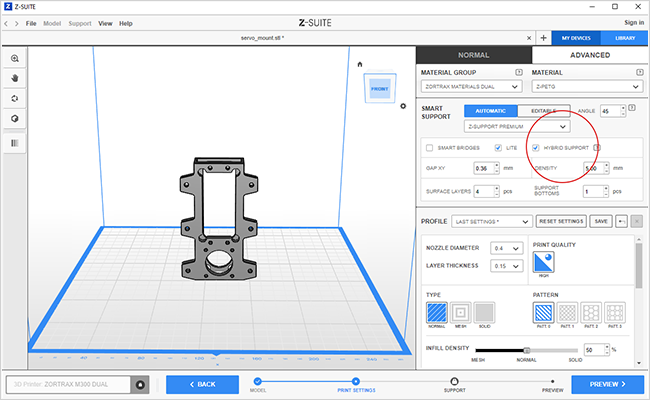

Hybrid Supports for Dual Extrusion

Hybrid supports is another feature tested and refined in the Z-SUITE Beta testing program all the way up to the production level it has reached in Z-SUITE 2.15.0. Hybrid supports are designed to make dual extrusion printing faster and save support material at the same time. When the “hybrid-supports” option is selected, the M300 Dual and the Inventure will print supports out of standard, non-soluble material with an exception of points where the support is planted into the model’s surface. Those contact points are printed with the water-soluble support filament.

Hybrid supports are the middle of the road solution between standard and water-soluble support structures.

This way, we have made the printing process faster because the printer spends less time on switching materials. At the same time, supports still can be removed hands-free, by rinsing the model in water, and leave no marks on the model.

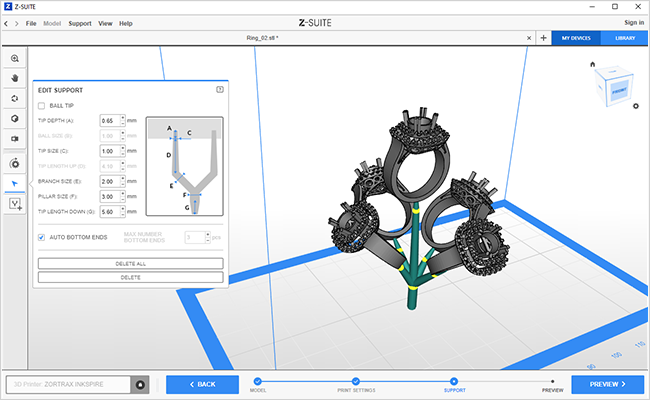

Tree Supports for the Inkspire

Tree supports are a smart way of supporting resin 3D printed models that have been designed with jewelry making in mind. In a typical jewelry-making process, multiple investment patterns are printed out of castable resins. Then, after support removal, those patterns are arranged on structures called casting trees, which are covered with an investment like gypsum and placed in a furnace. The purpose of such trees is to create space for a castable resin to flow out of the investment during the burnout procedure. The same space is also necessary to pour target materials like gold or silver, which are supposed to replace the burned-out resin. Tree supports make this process easier and faster.

Tree supports enable adding support structures that can also serve as casting trees.

Examining the geometry of casting trees, we concluded that after a few tweaks they can also support the models during the printing process. Therefore, we have included a tool for building such tree supports in Z-SUITE 2.15.0. Jewelers can now print the entire casting tree and completely skip support removal. They can do this because the tree support structure also serves as a path for a burned-out material to flow out of the investment, and the target material to flow into it.

Dedicated for investment casting, tree supports can be also used with standard materials where they save resin and make the printing process faster.

New Special-Purpose Resins

To ensure the best possible printing experience with the Inkspire, we have been working with market-leading manufacturers of resins to build thoroughly tested printing profiles for their materials. HARZ Labs, Dreve, and ApplyLabWork are joining external resin manufacturers featured in Z-SUITE with a wide selection of 23 materials. The ApplyLabWork offers a range of resins designed mainly for modeling applications. Their MSLA line of materials offers smooth surfaces and high-quality finish. Dreve range, in turn, is focused mostly on dental materials suitable for printing clear surgical guides and planning models. HARZ Labs is also a manufacturer of resins aimed at digital dentistry. Highlights in their range include Dental Cast material, which is made for casting permanent dental aids out of ceramics and alloys.

The ApplyLabWork offers a range of resins designed mainly for modeling applications. Their MSLA line of materials offers smooth surfaces and high-quality finish. Dreve range, in turn, is focused mostly on dental materials suitable for printing clear surgical guides and planning models. HARZ Labs is also a manufacturer of resins aimed at digital dentistry. Highlights in their range include Dental Cast material, which is made for casting permanent dental aids out of ceramics and alloys.

Z-SUITE 2.15.0 has tested, predefined printing profiles for radio-opaque and casting resins aimed at digital dentistry.

Another example is a Dental RO resin, where RO stands for radiopaque. This material is designed specifically for printing fillers which do not create artifacts in computer tomography scans.

Of course, Z-SUITE 2.15.0 comes with several other changes and stability improvements. Read the full changelog for an exhaustive list of its new features.