Reshape Your Industry and Redefine Your Company’s ROI in a Big Style – the Bosch Case Study

THE BACKGROUND: We believe that Bosch, the name of one of the leading tech giants in the industry is familiar to most of you. Apart from its long presence on the global markets, it is also industry-popular for its innovativeness and being an early adopter of the latest technologies as well as for constant development of its own state of the art solutions. One of the departments of Bosch company located in Mondeville, France decided to go for yet another innovation that is currently gaining its momentum in the industry – 3D printing technology. As it was out of question that such a big and well-prosperous corporation required nothing but professionalism, its first and choice were Zortrax M200 3D printers.

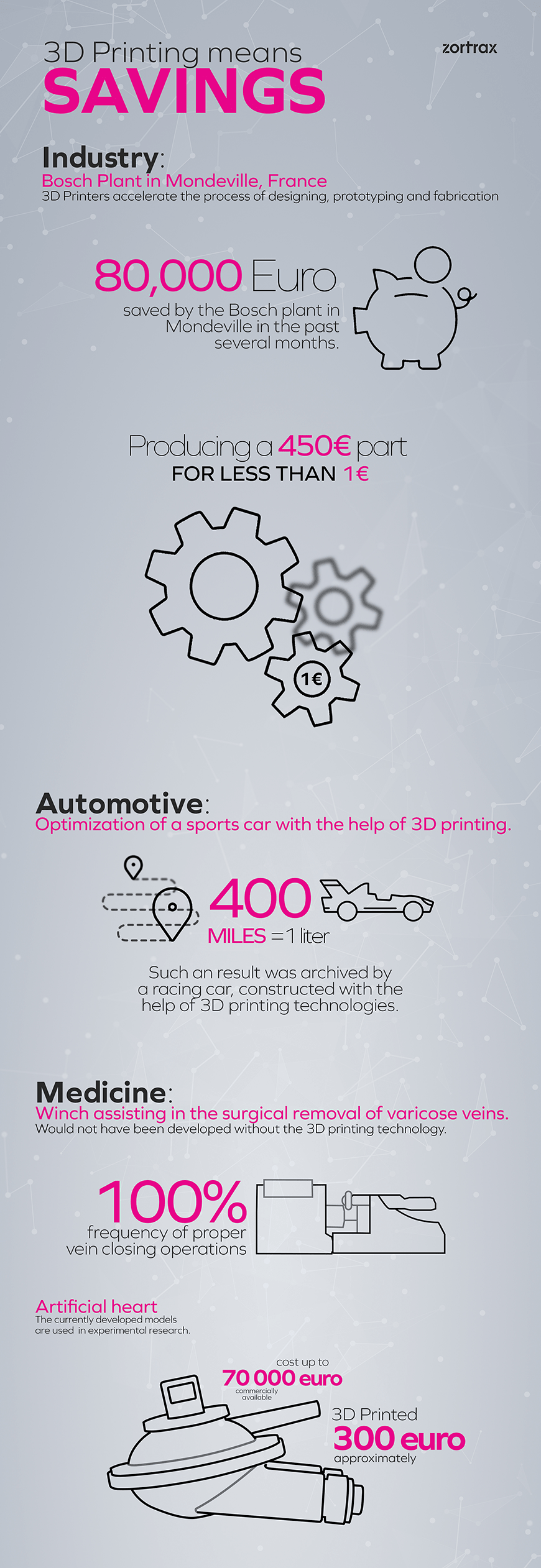

GOALS: The French department of Bosch Mondeville aimed at boosting the efficiency of producing and testing elements and at the same time cutting down on spending on the expensive equipment. They also wanted to check if is it possible to save over 80 000 euro during a year in a single plant. The Bosch team faced the decision to choose one of the plenty 3D printers available on the market. The parameters they put the main focus on were: ease of use, good price quality ratio, high print quality and reliability. Although the effects were seen almost immediately, they gave themselves a year to come up with a complex opinion on implementing Zortrax technology in their company.

THE PROCESS: The key parameters that determine the performance of a company were taken into consideration. As the company is known for being one of the pioneers when it comes to introducing the innovative technologies to their workplaces they started testing in which areas Zortrax 3D printers can actually improve the speed of production and efficiency. Apart from this, also the reliability of the Zortrax M200 was put into a real crash test to show the length of the maintenance free period of devices. As all the activities in the plant finally boil down to money, also the aspect of ROI and its speed was taken into account. The company used Zortrax M200 3D printers to 3D print special cases for plugs so they could be connected precisely to the hole of a device. This was essential as after the testing process during which a cable is plugged in and out several dozen of times it completely worn out and need to be replaced with a new one. Having succeeded at this area the R&D team from Bosch turned to implementing 3D printing for producing endings for the robots on the production line to check if they can use them instead of buying a whole set which costs approx. 450 Euro. The process of prototyping the parts on Zortrax M200 3D printers was said to be smooth and simple thanks to the dedicated materials and a range of compatible solutions.

THE RESULT: Thanks to implementing the 3D printing technology at Bosch, the company could prolong the lifespan of the components that were used to test the functionality of the devices. It helped to cut costs spent on the elements and also coordinated the whole testing process thanks to the fact that there was no necessity to change the parts such often as it used to be. Also after realizing that the endings for the machines with the estimated cost of 450 euro per set can be printed on Zortrax M200, the cost and time needed for ordering them were reduced resulting in total 80 000 euro saving. What is more it improved the fluidity of work as the parts were produced on demand within a couple of hours. It greatly eliminated the pauses at work that were caused by the necessity of waiting for the delivery of components. It is worth adding that thanks to the ease of use and out of the box solution, no extra time was spent on calibrating and maintenance of the 3D printers.

THE CONCLUSIONS: For those of you who are still not convinced if 3D printing is the right choice for boosting their business performance we have a quotation of one of the Bosch representatives: “Not using 3D printers in a company is a real mistake”. We hope that this robust statement will leave you with some food for though or become a spark to inspire you to look at your business from a slightly different angle. However, if some of you already dare to change or complement the old ways of manufacturing, should know that they will have the support on our side and the visible facts that prove that thinking outside the box means revolution in your performance, and not necessarily in your wallet. Those of you, who need more hard data should check our infographic with all the facts and figures and watch the video statement from Bosch.