The Complete Guide: How to Avoid Warping in Your 3D Prints

Summary

- To avoid warping, it's crucial to maintain stable temperature inside the printing chamber.

- PLA-based filaments are less prone to warping than ABS-based filaments.

- ABS juice significantly increases models' adhesion to build platform.

Warping is one of the most common issues any 3D printing enthusiast has faced. It rarely happens that warping causes some serious and dangerous failures. However, it may render your models completely unusable, even though you try your best to get rid of it in post-processing. Here’s why warping occurs and what to do when it happened to you.

The Basics

Most often, warping appears when a model cools down while it is still being printed. During that process, a material shrinks, and as a result contraction leads to stressFacts Warping is caused by stress resulting from material’s shrinking during cool down. Large models are more susceptible to warping. The more dense the infill, the more likely a model will warp. that is stretched out along the model’s bottom surface. Thus, the corners of the model curve, point upward, and deform the 3D printed object. Generally, this issue occurs in large models with a higher infill level, as there is more material prone to shrinking. In order to save your time on fixing prints that got damaged due to warping, there are a few easy steps that need to be followed.

In most cases it suffices to print with a raft and use a 3D printer with a heated, preferably also perforated platform.

Keep It Warm and Clean

First of all, it is extremely important to ensure proper printing conditions, in which the ambient temperature is not too low. Facts The higher the cool down rate, the higher the risk of warping. Keeping a build platform clean guarantees it stays even. Ambient temperature should not drop below 23 °C. The quicker the part is cooled down, the greater stress is placed on the model. That’s why it’s important to isolate the printing chamber from the environment covering its sides and top. Remember to make sure there are no draughts or air-conditioning turned on in the room.If possible, check if the temperature in the room does not drop below 23 °C. Once the proper printing conditions have been ensured, it’s significant to clean the platform. Your models will definitely stick much better to a surface that is free of dust or any liquid substances. Additionally, make sure there are no material residues between the build plate and the heatbed. Material remnants can create bulges underneath the plate as models printed on an uneven surface will gain a disfigured shape.

Once the proper printing conditions have been ensured, it’s significant to clean the platform. Your models will definitely stick much better to a surface that is free of dust or any liquid substances. Additionally, make sure there are no material residues between the build plate and the heatbed. Material remnants can create bulges underneath the plate as models printed on an uneven surface will gain a disfigured shape.

Calibration and Choosing Filaments

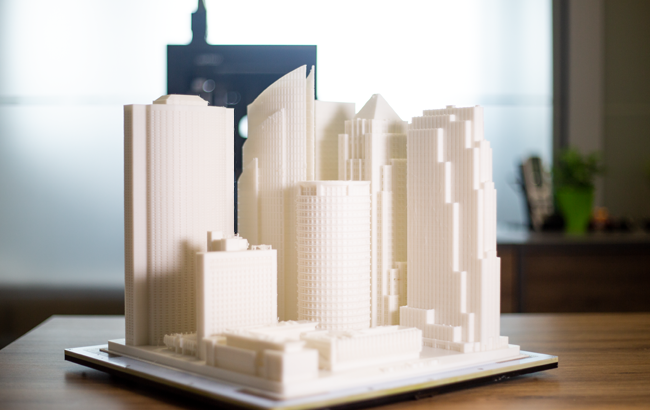

When the platform has been maintained, it is time for its calibration. Setting a proper distance between the nozzle and the perforated plate is crucial in printing the Facts Proper platform calibration significantly reduces warping. Making walls thiner and reducing infill brings the risk of warping down. Go for PLA-based materials or use ABS juice when you need ABS. first layer, which has a significant influence on the whole model. If the platform is too far from the nozzle, the material needs to cross a longer distance, which means it becomes cooler and loses its ability to stick to the platform. The same rule applies to all the subsequent layers – if the appropriate layer height has not been established, the layers will not adhere to each other. Warping in small prints is barely visible, whereas in prints exceeding 100 mm deformations may be easily observed. Thus, when printing larger objects, it is significant to choose a material with lower shrinkage. Remember that PLA-based filaments usually shrink very little. However, if you need to use an ABS-based material, design your model in such a way that it has thinner walls and reduced infill. The less material is used, the smaller the chance the model will curve as the internal pressure of the cooled down material is relieved.

Warping in small prints is barely visible, whereas in prints exceeding 100 mm deformations may be easily observed. Thus, when printing larger objects, it is significant to choose a material with lower shrinkage. Remember that PLA-based filaments usually shrink very little. However, if you need to use an ABS-based material, design your model in such a way that it has thinner walls and reduced infill. The less material is used, the smaller the chance the model will curve as the internal pressure of the cooled down material is relieved.

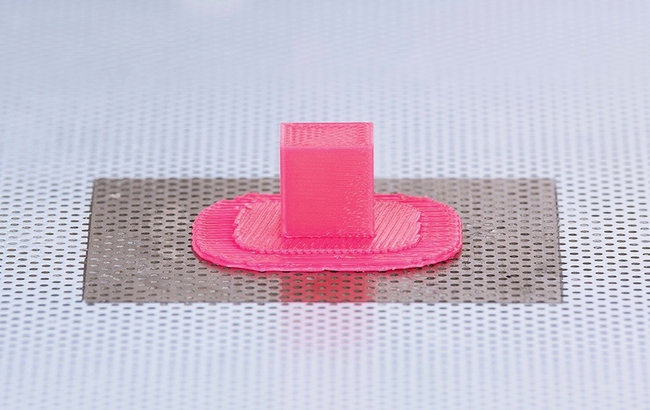

Juice It Up

In addition, you can prepare so called ABS juice. The ABS juice is an easy-to-prepare mixture made of an ABS-made material shreds and acetone. Once the mixture is ready, apply it on your build platform. Even a thin coat of the slurry significantly increases models’ adhesion to the platform’s surface.

To prepare the mixture, you can even use rafts or support structures from your past prints. A full tutorial showing how to make such a juice is available here.