How Mold Manufacturer Imold Saved 144 Working Hours

Imold , an Italian based mold manufacturing company has recently proven that the possibilities of 3D printing can go far beyond its primary purposes.

Imold is a mold manufacturer, operating in the fields of automation and mechanical construction. Imold is providing a complete solution package in precision injection molding to customers, from analysis and design to manufacturing. They are focused on how to “match the manufacturing process to the increasing demand for performance and cost-effectiveness”.

The company is using professional tools in order to improve their service. Machines used for injection molding and mechanical construction are often exploited more than the average usage. Imold is making sure products are delivered on time and within budget. That is why timing and efficiency is so crucial here.

Zortrax M200 is used by Imold staff for prototyping mainly electronic equipment enclosures. They plan to use it for functional parts as well. Recently they have used M200 for completely different purpose though:

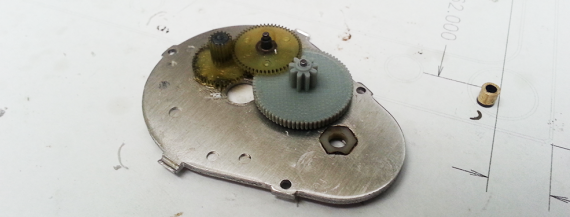

“A few days ago a component of one of our machines failed. It was a very small gear inside a motor-driven lubrication pump, an extremely important part of a machine that works 24/7. The machine is crucial for our manufacturing process.

The spare part was due for delivery in 6 days so it would have lost 144 working hours.

After a little hesitation we have decided to try to print it out with the M200. Something that seemed a desperate attempt because some features of the gear were smaller than the smallest admissible thickness of the printer! In fact, it took a couple of trial and error prints, but eventually we came out with a gear that could be installed and it worked!

Yes of course I could not expect that it was as durable as the original part – made of a special polyamide, but it lasted EXACTLY 6 days!!! In time for the original spare part.”