List of updates & upgrades

There wasn’t any news from us recently, so we post the list of new updates below.

Update in auto-calibration of the platform

In the first version of our auto-calibrated platform, the printer head touched each of the 5 calibrating points and gave the alert when one of the point was on improper height. After this, the user was able to change the position of this point by screws. Why is checking by the calibrating points necessary? Because the inclination of the platform can be easily left unnoticed but still can influence heavily on the printed model. Within some required firmware updates we’ve improved this process and excluded the need of leveling by screws.

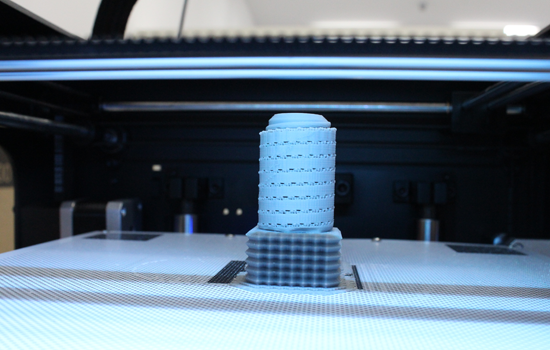

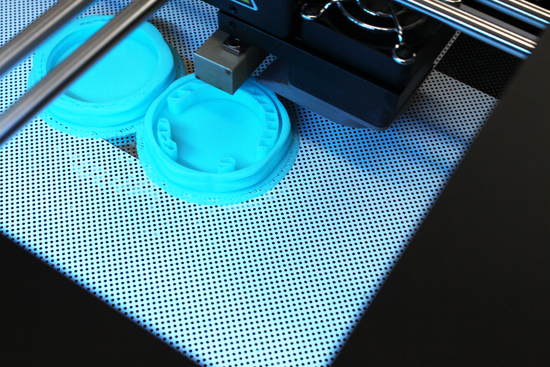

After our update, Zortrax M200 is able to start printing without any changes in the position of the platform. We’ve added special algorythm, which calculates the difference between the lowest and the highest point of the platform. The printer can predict the inclination of the platform and put special raft surface in order to achieve flat base before the first layer of the print.

Raft surface and first layers of the print

Update in support generation

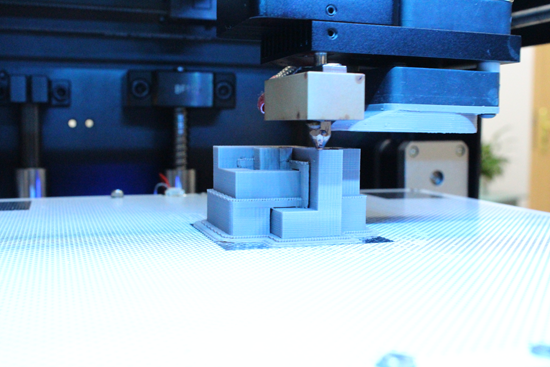

We’ve optimized the support structure, so now the volume of material used to build support is as small as it’s possible.

Model with the support structure

Additionally, this structure is quite different than the model surface structure. It allows you to easily remove support with no (even the smallest) marks on the object.

We recommend to use support structure in every print but it’s possible to print simple objects with sloping walls without support. Our easy-to-remove support technology allows to print really complex models.

Update in layer precision

The resolution of the print is one thing – the second is the layer precision. Low layer resolution does not quarantee the best quality when there are some bugs in printer’s firware and software. We’ve been working on head temperature settings and acceleration of stepper motors in order to achieve the best results on model surface (with no imperfections, irregular layers, edges and horizontal traces).

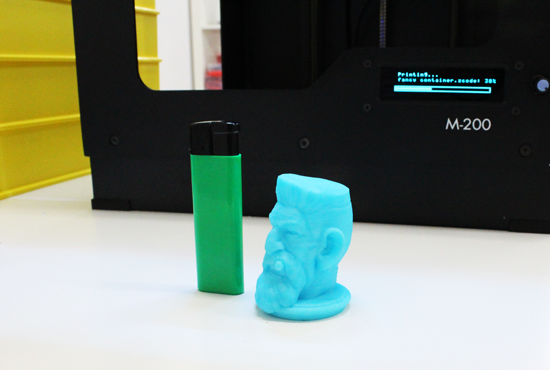

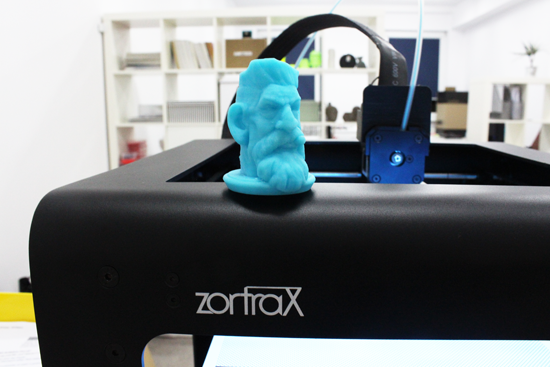

Layer precision guarantees smooth surface and walls even when we use low resolution. Thanks to the new modifications, model printed with 200 microns resolution can look like printed with 50 microns on other 3d printers. The result is the same, but the model is printed 2 times faster.

With all these new software and firmware solutions, we’re launching the new printing technology called Layer Plastic Deposition©. By comparing with all FFF 3D printers on the market, we’ve achieved the best results in printing with ABS filament and support structure from the same material and one extruder.

Flexible and durable Z-ABS

Summary

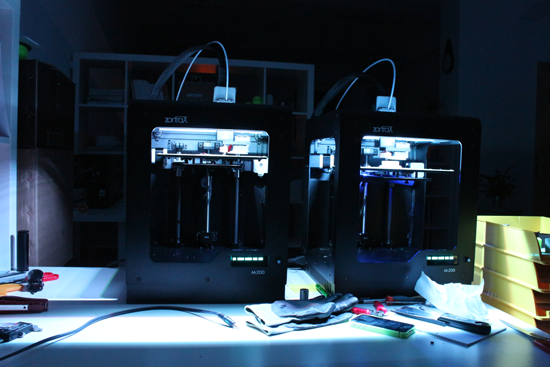

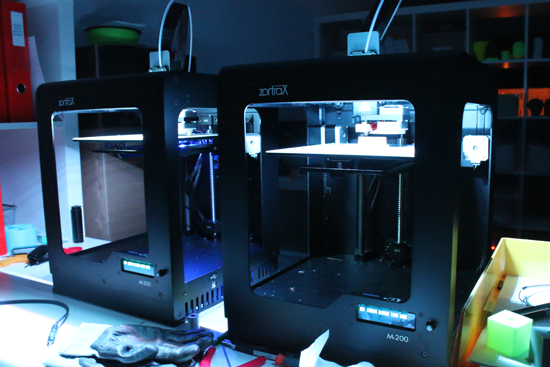

Zortrax M200 hardware is completed and everything works properly, we’re testing printers all the time and with different models. Firmware requires some changes after last modifications. Every new option and fragment of code cause big interference with information architecture. The reason why we have to keep all printers from the first batch is that we have to test modifications on all machines. Only in this way we can keep the consistency and accuracy during the testing process.

As you can see above, the results are better and better with every change. We apologize for contact problems again – the whole team is involved in achieving the goal – delivery of the best 3D printer. We can estimate that we need 2 additional weeks to test firmware with all printers and send the Zortrax M200.

Thank you,

Zortrax Team

(directly from the printing lab)