Introducing the Toughest Resins in Zortrax Portfolio

Summary

- New, exceptionally durable photopolymer resins with distinctive features enter the material range for Zortrax Inkspire.

- Zortrax Resin Tough is targeted at both engineers and hobbyists.

- There are three variants available: White, Grey, Clear.

We’re excited to announce another premiere for Zortrax Inkspire. Zortrax Resin Tough is our new 3D printing resin with unique properties, including high toughness and impact resistance. The resin is available in three variants: White, Grey, and Clear, each with slightly different and distinctive features. In this blog post, you’ll learn how you can use Resin Tough to your advantage and implement it in your projects.

Reinforced Durability

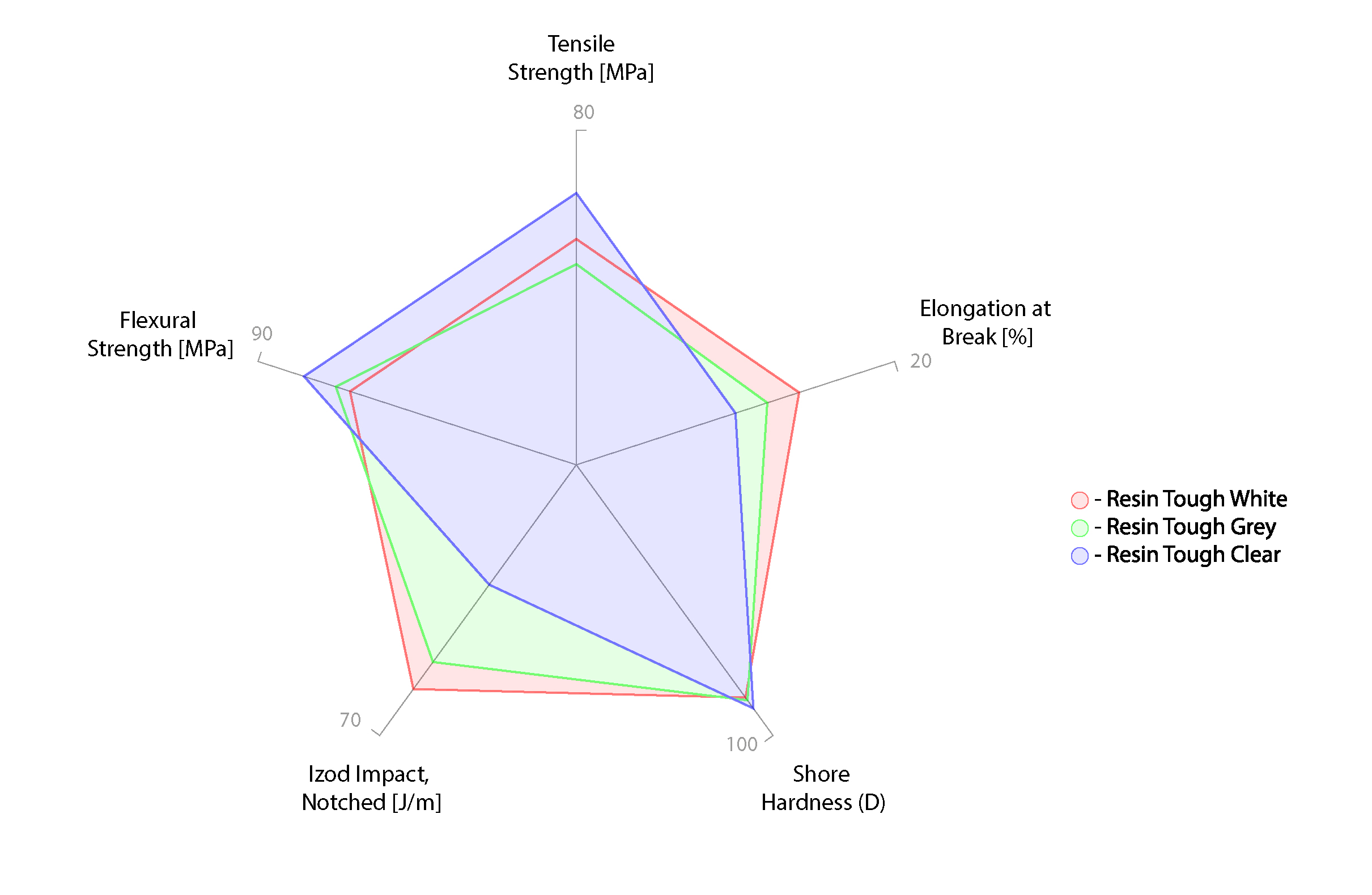

The first notable feature of Zortrax Resin Tough is reinforced toughness. This parameter was measured on printed samples in hardness and flexural tests. Both tests determined high resistance to bending and indentation of all three variants of the resin. The test results are presented in the graph below.

Comparison of technical properties of the three Zortrax Resin Tough variants.

Resin Tough White:

Shore D 86.0 / ASTM:D2240-05

Izod Impact, Notched 58.1 KJ/m2 / ASTM D256-10

Flexural Strength 63.8 MPa / ASTM D790-10

Tensile Strength 54.3 MPa / ASTM D638-14

Elongation at Break 13.9% / ASTM D638-14

Flexural Modulus 1586.8 MPa / ASTM:D790-10

Resin Tough Grey:

Shore D 84.0 / ASTM:D2240-05

Izod Impact, Notched 51.4 KJ/m2 / ASTM D256-10

Flexural Strength 68.2 MPa / ASTM D790-10

Tensile Strength 48.3 MPa / ASTM D638-14

Elongation at Break 12.3% / ASTM D638-14

Flexural Modulus 1674.2 MPa/ ASTM:D790-10

Resin Tough Clear:

Shore D 90.0 / ASTM:D2240-05

Izod Impact, Notched 30.78 KJ/m2 / ASTM D256-10

Flexural Strength 77.3 MPa / ASTM D790-10

Tensile Strength 65.3 MPa / ASTM D638-14

Elongation at Break 10.4 % / ASTM D638-14

Flexural Modulus 1789.3 MPa / ASTM:D790-10

As you can see, other tests showed minor differences in the resins’ technical parameters. If we compare those results, we can notice that Zortrax Resin Tough Clear has higher values of tensile strength and modulus of elasticity, whereas Resin Tough White/Grey shows higher impact strength and elongation at break. Also, Resin Tough Clear is slightly harder in comparison to the White and Grey variants.

Perfect for Engineering

Nevertheless, such measurements prove that any type of Zortrax Resin Tough can become the perfect choice for professionals who look for engineering solutions in their work. 3D models are tough and don’t break easily under loads. This means the material can fit applications that require good durability and extended lifespan, for example, jigs and fixtures, consumables for production lines, or engineering prototypes for testing. Precise resin prints can also be implemented in product development processes or even end-use products and electronics casings.

BIKE WRENCH. Fully functional 3D printed tools can be tailored to specific needs.

Wide Application Range

All three resins are versatile enough to be introduced in many fields and can open up multiple possibilities. The resins have low shrinkage, and the printed items have smooth surfaces and sharp details. Such features can become handy for both professionals and hobbyists. High quality of 3D prints allows makers to assemble multiple elements into one model with ease. Separate elements of movable mechanisms, functional prototypes, action figurines, or toys match each other perfectly, creating items suitable for performance evaluation or exhibition. Additionally, Resin Tough White shows improved resistance to yellowing, whereas Resin Tough Grey is highly scratch-resistant.

SHELF BRACKETS. Custom-made shelf brackets are durable enough to perfectly fit any home or office interior.

Transparency Properties

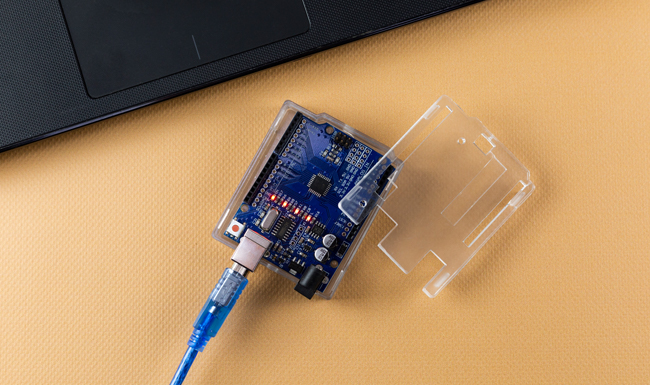

Another feature we’d like to highlight is a light-transmitting capacity of Resin Tough Clear. Prints made with this material combine unparalleled toughness and resistance to impacts with unique aesthetics, which in turn allow users to successfully create glass-like objects. The resin can be particularly helpful for prototypes that have to demonstrate what’s inside the object or designs where visual aspects are important for the project’s assessment. All these qualities make Resin Tough Clear the right material when you want to replace brittle glass elements in models for engineering, scientific research, or interior design. 3D prints can mimic glass in a variety of prototypes, end-use products’ casings, lighting elements, or decorative pieces. Translucency of ready prints can be further enhanced with several post-processing methods, including UV curing, sanding, or varnishing.

PCB ENCLOSURE. A transparent enclosure printed with Zortrax Resin Tough can be used to showcase PCBs or other electronics, and simultaneously protect such fragile elements.

To sum up, all three resins can easily be implemented when UV LCD printing in workshops, production halls, or design studios, and provide great results. Your precise and highly detailed resin prints can now gain distinctive properties and you can explore new application possibilities. As usual, we’re including dedicated printing profiles in a new Z-SUITE update (2.18.1), available from today in the Downloads section at the Support Center.