How Inkspire 2 and BASF Forward AM Resin Fill the Void for Custom Sports Gear

Summary

- Krzysztof Urban, working as a CAD designer, has developed functional bike lamps, using Zortrax Inkspire 2 resin 3D printer.

- The engineer 3D printed the lamps with BASF Ultracur3D RG 1100 B resin.

- The obtained small-sized lamps have a powerful light source, are highly durable and adjustable to different handlebar sizes.

Resin 3D printing is an effective tool for developing custom utility models in a variety of industries, like mechanical engineering, robotics, and automotive. A quality 3D printer, combined with high-grade, durable resins allows resin 3D printing to extend far beyond just prototyping. Read about the use case, where applying Zortrax Inkspire 2 UV LCD 3D printer and BASF Ultracur3D RG 1100 B resin translated into tangible benefits and a fully functional end product: high-resistant custom bike lamps.

Needs Form Ideas: A Market Shortage-Driven 3D Project

Krzysztof Urban, who works at Zortrax as a CAD Designer, is a true cycling enthusiast. He combines his passion for 3D printing with a passion for sports, utilizing additive manufacturing for his own individual needs. As he often cycles in the evenings and at nights, he desired to equip his bike with appropriate bike lights. He had been searching for powerful light source capable of illuminating the road well without shining strongly into the distance. It was supposed to clearly highlight the terrain near the bike and give a wide-angle view. He also wanted the lamps to be lightweight, durable, and not taking much space on the handlebars.

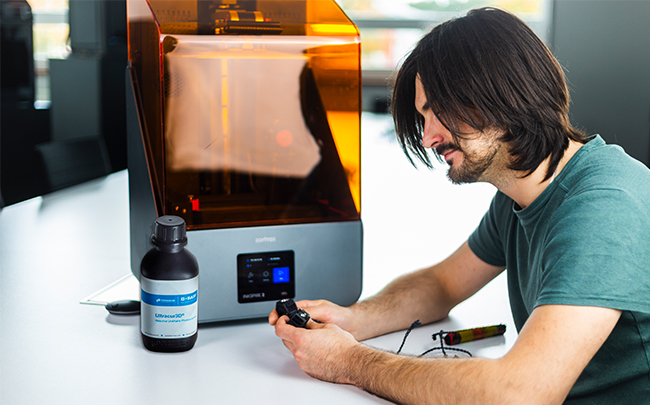

The picture shows Krzysztof assembling bicycle lamp housings 3D printed from BASF Ultracur RG 1100 B resin on Zortrax Inkspire 2 printer.

After a while, it occurred that the lamps available commercially did not meet those requirements. As Krzysztof pointed out: “Most bicycle flashlights on the market are relatively large, quite heavy, expensive, and do not necessarily meet my expectations in terms of optics.” Moreover, the battery in such devices, being itself a source of heat, is usually located close to the light source, also emitting much heat. In addition to the large size of the flashlight, this also affects the life of the LED which tends to overheat at full power. With a set of clear goals as for the target models, Krzysztof decided to construct the lamps himself, using Zortrax Inkspire 2 resin 3D printer.

Resin 3D Printing in Engineering and Sports: How Inkspire 2 Helped Develop Functional Bike Lamps

Workflow step 1: Designing Custom Bicycle Lamps

The first step in a creative process is designing the models. The engineer used Solidworks 2022 modeling software for that purpose. He gathered the components and assembled them into the smallest structure possible. Next, he thought about how to encapsulate it all while leaving the heatsink exposed so that the airflow would garner the emitted heat.

“I used the Inkspire 2 UV LCD 3D printer because of its advanced material base, high speed, and super accuracy.” – Krzysztof Urban underlines.

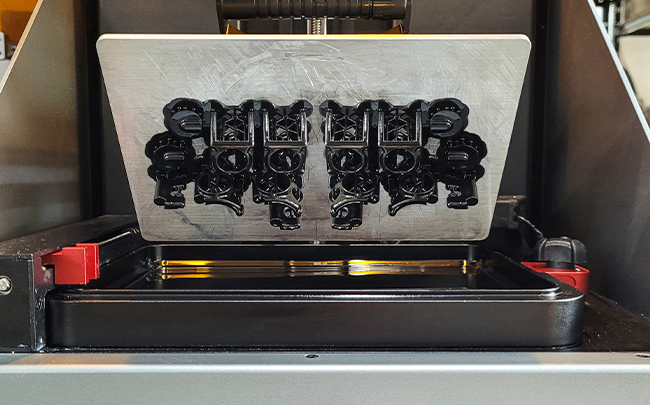

Due to the big workspace in the Inkspire 2, one can 3D print big resin models at one go, or place many smaller items on the platform. The lamps are small, so Krzysztof could 3D print many items all at once.

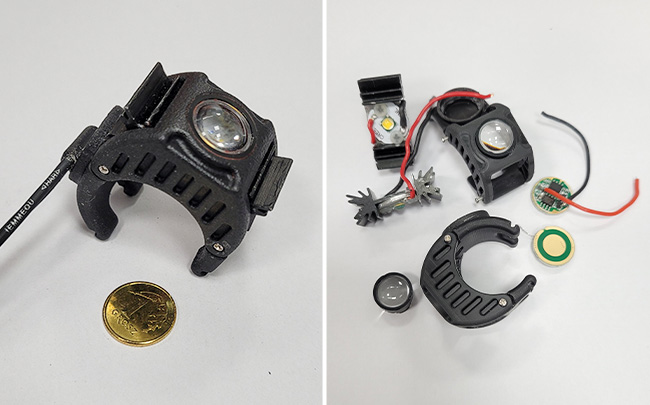

The picture shows the size of the model (left) and all the components (right).

Workflow step 2: Resin 3D Printing with Zortrax and BASF Resins

For cost-saving reasons, the engineer made first functional prototype with a relatively cheap yet high quality Zortrax Resin Tough Black. It was durable enough to verify the possible corrections in the design and conduct a series of tests. The target models were 3D printed using BASF Ultracur3D RG 1100 B resin, which is a new color variant of BASF Ultracur3D RG 1100 resin available in our portfolio. The author of the project chose this particular resin due to its exceptionally high strength and heat resistance. The most important 3D printing parameters were as follows:

- Layer height: 0.05 mm

- Printing time: 4 h

- Material usage: 17.69 ml

- Slicing quality: High

Krzysztof raised the models relative to the platform by 5 mm. Having generated the default Medium supports, the designer removed a few where he found them unnecessary.

Thanks to a big build platform in the Inkspire 2, several resin bike lamp models could be 3D printed at the same time.

Automatic Post-Processing of Resin 3D Prints with Zortrax Cleaning and Curing Stations

Workflow step 3: Post-Processing the Bike Lamp Models

Here, the engineer washed the resin 3D prints for 5 minutes in Zortrax Cleaning Station, an automatic post-processing device recommended for the Inkspire 2. Then, he removed the supports and gently cut off their remains with a knife. Later on, the models were cured in Zortrax Curing Station for about 7 minutes. Finally, Krzysztof painted the housing with black structural varnish to obtain a desired polished look.

Workflow step 4: Fitting in the Electronics

With the ready models, it was now the time to mount the components and fit in the electronics.

Mounting the electronics in bike lamps 3D printed from BASF Ultracur RG 1100 B resin.

The Inkspire 2 and BASF Resins: The Perfect Match For Durable End-Use Parts

Zortrax Inkspire 2 resin 3D printer used in the project operates in UV LCD technology which means manufacturing objects from Photopolymers (UV resins). It is characterized by relatively isotropic strength properties. It was particularly important here because of the housing’s geometric compilation. With a layer height of 0.05 mm and an accuracy of 50 μm, the reproduction of the model without CNC machining is accurate and no layers of the print are visible. The custom bike lamps were ready in slightly less than 4 hours. The final models have an external power source and all the parts are conveniently enclosed in a 3D printed housing.

The picture presents the resin 3D models mounted on the handlebars (left) and the view Krzysztof has on his bike while using them (right).

Properly post-processed high-class engineering resin, BASF Ultracur3D RG 1100 B guarantees that the lamps will survive much on the roads in any weather conditions. The final parts, 3D printed with the use of this resin, are also versatile and compatible with many sizes of the handlebars.

“A compact case accommodates the LED together with the heatsink and driver, and allows for a quick mounting on the steering wheel. It gives the liberty of adaptation to different handlebars diameters. The whole set was symmetrically duplicated on both sides of the handlebars. That gave a total of 20 W and 2400 lm and a wide perspective during night driving. The bike lamps are also highly durable. Obtaining such results without the Inkspire 2 and BASF would have been much more costly and time-consuming,” Krzysztof Urban concludes.