Improved Rotation Optimization Tools in the Z-SUITE 2.7.4

Summary

- Z-SUITE 2.7.4 release is available for download.

- It features more powerful Rotation Optimization tool that now works with Zortrax Inkspire resin UV LCD 3D printer besides Zortrax FDM 3D printers.

- Automatic seam generation has been improved to make the seam less visible.

The latest Z-SUITE comes with a number of new features enhancing the user’s work experience with Zortrax FDM 3D printers and Zortrax Inkspire resin UV LCD 3D printer. It also comes with added support for Zortrax Apoller smart vapor smoothing device. Here’s a brief guide to the most important improvements.

More Powerful Rotation Optimization

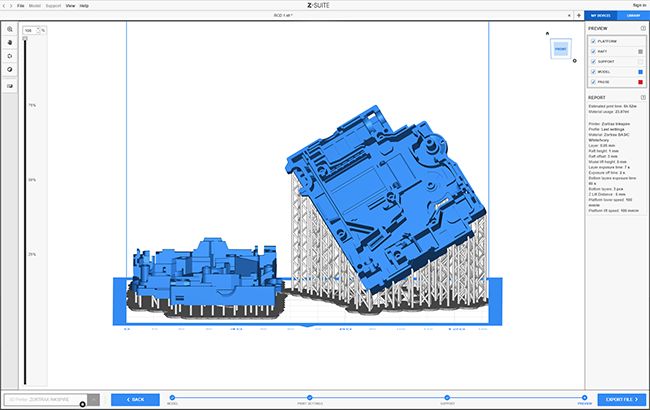

Rotation Optimization tool is a built-in Z-SUITE algorithm optimizing models’ position on the build platform to efficiently place support structures necessary to print them properly.Facts Support structures’ placement can be optimized by properly arranging models on the build platform. It can be done by hand but takes a lot of experience. Z-SUITE can perform the same kind of optimization task automatically even in challenging resin 3D printing technology. In the earlier update it has been introduced to all Zortrax FDM 3D printers. Now it is available for Zortrax Inkspire as well. Experienced users usually arrange their models to print with minimal amount of support. This way they reduce both the printing time and the cost of filaments or resins. Z-SUITE software can do the same kind of optimization task automatically, even when working with more challenging resin UV LCD 3D printing technology. This way unexperienced users can get high-quality prints on Zortrax Inkspire.

The Rotation Optimization tool is available at the Model step in Z-SUITE. Once the tool is activated, a user can choose a set of criteria that an algorithm has to meet when arranging a model’s position. For FDM 3D printers it is possible to minimize to supports footprint on the model, minimize the support structures’ volume, maximize the surface supported by the build platform, and to minimize the model’s height.

In printing on Zortrax Inkspire, the tool can minimize the supports footprint on the model, maximize the surface of the model supported by build platform, minimize the model’s height. Additionally, Rotation Optimization tool can work when the Model Lift option is chosen. The Model Lift option means that the model will not touch the build platform, but will rest entirely on support structures. If this option is chosen, the algorithm won’t calculate a model’s position maximizing the surface supported by build platform, as the two are mutually exclusive. Once the desired set of criteria for optimization and the supports angle are chosen, Z-SUITE suggests possible models’ arrangements that meet them.

Once the desired set of criteria for optimization and the supports angle are chosen, Z-SUITE suggests possible models’ arrangements that meet them.

Support of Zortrax Apoller

Zortrax Apoller smart vapor smoothing device is an innovative solution for automated post-processing of FDM 3D printed models. Facts Zortrax Apoller is a device for automatic vapor smoothing. It now can be found in Z-SUITE’s My Devices panel. The software shows the Apoller’s status and control the device remotely. The latest Z-SUITE makes it possible to control the Apoller remotely over Wi-Fi and monitor the smoothing process in the My Devices panel. In the panel a user can see the Apoller’s current status. The device can be ready to smoothing which means it is in a stand by mode, smoothing, which is to say that the models are being smoothed at the moment. Finally there is a smoothing completed status which says that smoothing is done and models can be taken out of the smoothing chamber.

A user can remotely abort the already running smoothing process by clicking the abort button. Z-SUITE also displays the time remaining to the end of the current smoothing session.

Other Changes

Other changes include better automatic seam generation which makes the seam less visible, an improved quality of printsFacts Quality of Z-ABS 3D printing on 0.29 layer height has been improved. Quality of prints with Zortrax Resin BASIC and Zortrax Resin DENTAL have improved on Zortrax Inkspire. Nylon-based profiles have been added for M Series Plus 3D printers. with Z-ABS on M Series and M Series Plus 3D printers with 0.29 mm layer height, and fine tuned exposure times for printing with Zortrax Resin BASIC and Zortrax Resin Dental on Zortrax Inkspire 3D printer. Last but not least, nylon-based profile has been added for the M200 Plus and M300 Plus 3D printers.

Here you can find detailed manuals for Rotation Optimization.

Most important Z-SUITE 2.7.4 features include:

- Rotation Optimization Tool works with Zortrax Inkspire

- Choice of rotation optimization criteria has been added

- Automatic seam generation has been improved

- Zortrax Apoller has been added to My Devices panel

- Nylon-based profile has been added for M Series Plus 3D printers

- Minor bug fixes and stability improvements