Custom-made Helmet for a Cat with Zortrax Desktop Printer

Summary

- A French influencer, Remy Vicarini, has designed and 3D printed extraordinary helmets for his cat, Cathode, with the use of Zortrax M200 Plus desktop printer.

- The filament Remy opted for was Z-ULTRAT, due to its durability, hardness, and smooth finish of prints.

- Apart from custom-made helmets for his cat, Remy uses his Zortrax 3D printer for creating multiple objects of everyday use whenever he needs them.

3D printing technology allows for the creation of extraordinary objects, otherwise impossible to obtain. This can be backed by numerous examples, one of them being the recent project by Remy Vicarini. With the use of Zortrax M200 Plus, a French influencer, known by the nickname mon_copain_ray, has created a custom-made helmet for his cat, Cathode. The helmet now serves as much-needed eye protection for Cathode, Remy’s inseparable companion in sports. This is what the process of turning his concept into a real utility object looked like.

Cathode in a fully-finished helmet by Remy Vicarini, with her portrait beside.

Designing and 3D Printing the Helmet

Workflow step 1: Measurements and Digital Design

The creative process begins with measuring Cathode’s head. In order to do so, Remy places the pieces of aluminum foil around the cat’s head and forms a hollow ball of that size. Then, he moves on to digital design. With the mold at his disposal, the creator transfers the measurements to PTC Creo design software, forming the digital model. Once it’s ready, the obtained .stl file is uploaded to Z-SUITE, where it is sliced and prepared for 3D printing. „With Z-SUITE it’s super simple. I see my design appear and the first thing I do is positioning it in space. My trick is to always put the surface that will be the most visible after the print at the top, to get the best surface finish,” Remy underlines. As this software is truly intuitive, it is not a challenge to achieve the optimal settings – it advises its users on the most efficient position of the model, support angles, and other parameters crucial for minimizing the time and material usage for a given print.

Workflow step 2: 3D Printing

Now, Remy uploads the model of a helmet, prepared in Z-SUITE, to his Zortrax 3D printer, connecting the USB stick to the device. All the files ready for 3D printing appear at this stage on the printer’s screen – the creator just picks the one he wishes to print. The filament Remy selects for Cathode’s helmet is Z-ULTRAT due to its durability, hardness, and smooth finish of prints. As the influencer states, „I love using Z-ULTRAT, the workmanship is still very good, and the material is robust with a shiny appearance, and the prints are hard and smooth. I always choose that one.” Regardless of the material selected for a particular project, the assets of Zortrax M200 Plus stay the same. Remy confirms that ease of use, desktop size, and, most of all, reliability are its key advantages.

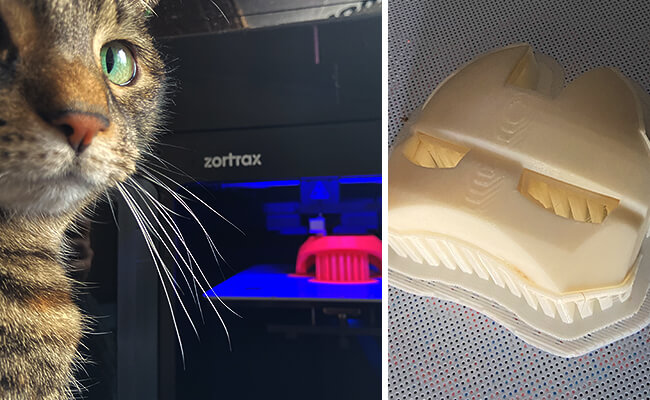

Cathode supervising the 3D printing process.

Giving the Models their Final Look

Workflow step 3: Post-processing

Once the prints are ready, the influencer moves on to their post-processing. In this step, it is essential to remove the support structures, which might sometimes be challenging, especially in some hard-to-reach corners. Whenever there is such a need, Remy takes his time to scrap the leftovers of supporting material with a special tool. In order to obtain a smooth surface of the helmets, he also uses sandpaper, thoroughly polishing any irregularities. The helmets prepared in such a way are ready for the last stage, which is painting. After the final touches of the paintbrush, the fully functional and eye-pleasing objects are obtained.

Having 3D printed the models, Remy removes the supports, polishes the prints with sandpaper and paints them to give them the final look.

The helmets for Cathode, though do not constitute the protection in case of a fall, perfectly shield her eyes from the wind while doing various sports with Remy, be it cycling, motorcycling, or any other activity Remy wants Cathode to accompany him in. “The 3D printed items have worked every time, whatever the shape of the helmet is. It’s a real success!”, Remy Vicarini assures. Although mon_copain_ray is best known for his projects for Cathode, he creates more than garments for his gorgeous cat with the use of Zortrax M200 Plus. „I make all the parts needed to make my life easier or to replace any broken parts for the items of everyday use with this printer. For example, to hold my shower palm, to make a phone holder for my motorbike and recently for a glasses project for the people who can only communicate by blinking their eyes! Zortrax makes all my ideas come true.”

Thanks to Remy Vicarini’s imagination and 3D printing technology, Cathode’s eyes are now properly protected and the cat is ready for further adventures.