Creating a Unique Volta Charger with Zortrax 3D Printers

Summary

- Metafora, an Italian Design collective has developed a prototype of an ultimate universal charger – Volta Spark, using Zortrax 3D printers: M200 Plus and the Inkspire.

- The materials Metafora used in the process were Z-HIPS and Z-PLA Pro as well as Zortrax Resin BASIC Grey.

- Zortrax M200 Plus proved invaluable in rapid prototyping and testing multiple design solutions whereas the Inkspire, due to its precision, has served as an ideal tool for the final concept of the versatile cable.

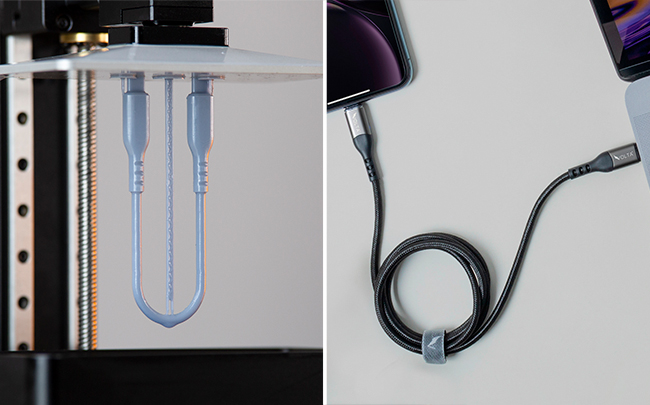

Metafora, an Italian design collective, recognizes the benefits of 3D printing for their business and implements it into various projects. The group of designers have recently developed a prototype of a versatile charging cable for an Australian company called Volta Charger. Volta Spark, as that’s the name of the project, combines utility with premium looks. To make this project come to life, the creators at Metafora used Zortrax M200 Plus in the initial stages of the design process and Zortrax Inkspire resin UV LCD 3D printer while testing the final prototype of the charger. This is what the prototype and the final product look like.

The prototype of Volta Spark, 3D printed on the Inkspire (left) and the final product (right).

Designing and 3D Printing Prototypes

Workflow step 1: Digital Design

First, the designers make about twenty versions of the cable in 3D modeling software. Operating Zortrax M200 Plus LPD printer is quick and easy, which allows the team responsible for Volta charger to print as many versions of the design as they need in a short period of time and, most of all, at low cost. This significantly facilitates the process of introducing any desired alterations to the project. As Simone Alborghetti, designer at Metafora underlines, “The possibility to test the product several times is crucial here. Thanks to using a 3D printer, we can see both the 3D printed products and the renderings – both aspects are equally important. When you see the 3D printed products, you can understand the ergonomics, the proportions.”

Before the printing process is initiated, the model of a cable is sliced in Z-SUITE.

Workflow step 2: 3D Printing

Once the various versions of the design are ready, they have to be uploaded to Z-SUITE, software that Zortax provides with all the printers it offers. Digital models are sliced here layer by layer and prepared for the 3D printing process. In the case of Volta charger project, Metafora Design decides to apply 0.09 layer height. As for the materials used, they select Zortrax Z-HIPS and Z-PLA Pro since they aim at the top accuracy of the finish. Having read the specification for each material, the designers think Z-HIPS and Z-PLA Pro suit their needs best. As for the final prototype printed on the Inkspire, the material of choice is Zortrax RESIN Basic Grey.

The final prototype of a versatile charging cable printed on the Inkspire with the use of Zortrax Resin BASIC Grey.

After support removal, the prints do not have to undergo any further post-processing — the creators are pretty satisfied with the “raw” versions of the models. After comparing many physical items of different dimensions and details and testing them for accuracy, Metafora Design is now able to pick the ultimate prototype. The choice is dictated mainly by the details, which, according to the founder of Metafora collective, make or break a given project. “A cable just has to have a wire and a top, so most of them are very similar. It’s the details that do the job here. One may not know all about design, but can definitely see which cable is cheap and which is premium. It’s all about the detail.” With the detail so important in Volta Spark, it’s no wonder the Inkspire was chosen for the final prototype, as it’s known for its excellent precision and high quality prints.

Two variations of Volta Spark cable tips on the platform right after the Inkspire has completed the printing process.

Turning a Prototype into a Target Project

Workflow step 3: Choosing the Target Materials

In this step, the designers take care of the final engineering of Volta Spark. They make sure that it fulfills its purpose and meets the required industrial standards. The key feature distinguishing Volta Spark from all the other chargers, is its ability to charge many different devices. Hence, the creators have equipped one end of the charger with an open magnet. With the use of one of the three dedicated tips, this open end can be turned into a USB-C, Lightning or Micro USB charger. In order to ensure high resistance and durability of the charging cable, military-grade materials, such as an ultra-strong tangle-free nylon, have been used in the project. “The Volta Spark is able to charge any device. It’s compatible with Apple MacBook Pro, iPhones, Samsung Galaxy, Google Pixel XL, or any micro USB devices. Imagine, one cable that charges every device you own! Moreover, it’s been designed to last. In fact, it is the toughest universal cable currently available on the market!,” Metafora designers underline.

Various tips in Volta Spark allow the users to charge any device, e.g. Apple MacBook Pro, iPhones, Samsung Galaxy, Google Pixel XL and micro USB devices.

Surely, Volta Spark is going to make the lives of many easier. Just like 3D printing has made this project easier; completing it within just three months would not have been possible without Zortrax devices at Metafora’s disposal.

The military-grade materials used for Volta Spark make it the toughest and most-resistant universal cable on the market.