3D Printing for Education: Human Bone Models at Victoria University

Summary

- Victoria University in Melbourne, Australia, used 2 Zortrax M200 3D printers to print over 5000 plastic bones for osteopathy students.

- 3D printed educational aids increased pass rate from 89% to 99%.

- Victoria University wil use Zortrax 3D printers for future projects to improve teaching of medical and STEM subjects.

Osteopathy students at Victoria University in Melbourne, Australia, work with human bone models printed on Zortrax M200 3D printers. “In anatomy, students get their hands-on experience with cadavers in labs. Time in the laboratory is limited and academics wanted to maximise student learning by extending hands-on learning experiences beyond the laboratory classes”, says Dr Sonia Wilkie, a technology enhanced learning designer at Victoria University.

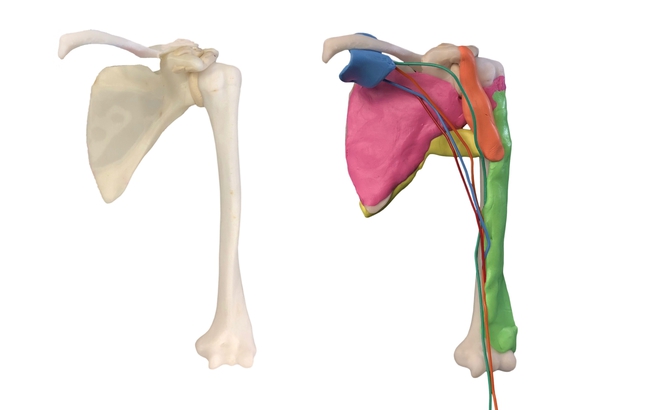

Educational upper limb models for osteopathy students at Victoria University.

“3D printed bones could be used in standard classrooms, and we could make a set of bones for every student”, she adds. 3D printed educational aids brought the exams pass rate up to 99% within 8 months.

Background

Victoria University has learning designers working with academics to make teaching more engaging for students. “Lectures themselves can be considered as passive learning”, says Wilkie.Facts Osteopathy students gain hands-on experience to learn human anatomy. University wanted to extend students hands-on learning experience beyond the laboratory classes. 3D printed human bone models offer a viable alternative. That’s why the university introduced active learning with various multi-media online tools, mostly images and interactive videos. But the real-life experience in anatomy courses was obtained through lab classes where students worked with cadavers, real human bodies donated to the university for scientific and educational purposes. “Hands-on learning experience in the labs is valuable. However access to the laboratories is limited to the timetabled classes. Academics wanted to extend student hands-on learning experiences beyond the timetabled lab classes, in order to maximise student learning opportunities. This was achieved by providing the students with their own 3D printed bone models” explains Wilkie.

200 sets of bones 3D printed at Victoria University.

Pass rate of osteopathy exams stood at 89%, but the team wanted to increase it. So, last year the university bought a Zortrax M200 3D printer. Academics running osteopathy courses were the first to see the potential.

Goals

The idea was to 3D print the bones of human upper limb (arm). Academics at the university wanted osteopathy students to have their own set of bones they could work with and take home. Facts University wanted students to own human bone models. The purpose was to help them memorize technical names of bones, tendons etc. Bones 3D printed by third-party providers would cost up to $AU 35 per student. , They hoped, memorizing technical names of bones, ligaments, tendons, and muscles would be easier. Each set of 3D printed bones was to come with modeling clay. With modeling clay students were to mold muscles, ligaments, and tendons on to the bones on the arm. The team’s first idea was to outsource the 3D printing. She and her colleagues went around asking for quotes. But those quotes proved daunting.

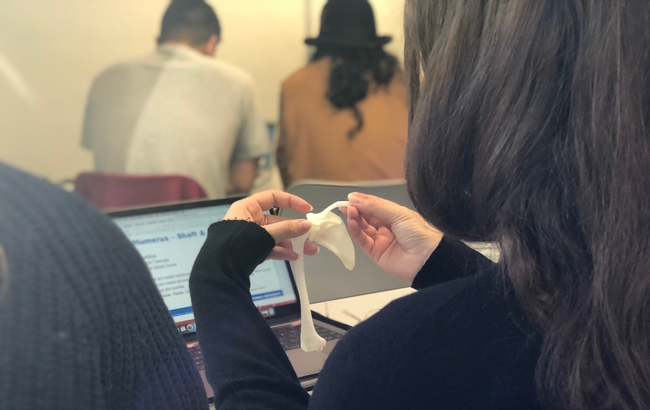

Victoria University students working with 3D printed bones.

Each set consisting of 6 items costed around 30 Australian dollars. 200 sets would set the university back between $5.5k and $7.5k. The costs broke down as follows:

| Provider | 1 set | 200 sets |

| Kerrys Hub | $28.06 | $5,611.49 |

| Calvinss Hub | $35.93 | $7,185.24 |

Process

Victoria University decided to print the sets on their own. Models of upper limb bones were downloaded from a publicly available repository. “We rescaled the modelsFacts University 3D printed bone models in-house on Zortrax M200 3D printers. It took 8 hours to print one set of bones on one M200. Cost of 3D printing in-house was $AU 1.50 per one set of bones. changed the orientation and amount of support to maximise production and minimise the amount of filament required” says Ghaith Zakaria, Wilkie’s fellow enhanced learning designer. One 3D printer could print one set of bones in about 8 hours. Two things quickly become apparent. First, one 3D printer wasn’t enough to print 200 sets on time. Second, given the costs of outsourcing, it was still cheaper to buy another Zortrax M200 than have the bones made by third-party providers. Because the sets were for students to keep, the team opted for budget Z-ABS filament.

Ghaith S. Zakaria and Sonia Wilkie, educators at Victoria University, with the 3D printed bones on the floor.

“That was the most cost-efficient way”, says Zakaria. Printing the bones in-house costed as follows.

| Item | Time | Weight (g) | Print Cost ($ AU) |

| Clavicle | 28m | 3 | $ 0.12 |

| Scapula | 1h 56m | 6 | $ 0.27 |

| Humerus | 1h 40m | 8 | $ 0.37 |

| Radius & Ulna | 1h 32m | 8 | $ 0.37 |

| Carpus | 24m | 2 | $ 0.09 |

| Metacarpals | 1h 34m | 2 | $ 0.28 |

| Total | 7h 57m | 33 | $1.50 |

Total cost per 200 students cohort was $300. The university paid $36.36 for a Z-ABS filament spool. Cost of material stood at $0.45 per gram.

Results

The bones needed no post-processing. Zortrax 3D printers produced models that could be used right after support removal. Two M200s worked nearly 24/7 for 8 months without a single failure. Facts Zortrax 3D printers worked 24/7 for 8 months without a single failure. Students got their own bone models and could keep them. 3D printed educational aids got the pass rate up to 99%. “Now each osteopathy student gets his or her own set of bones to keep. They can work with them, practice on them, and take them home”, says Wilkie. According to her, this way the learning experience became more tactile. “The 3D models extend students time and practice learning how the different bones operate. Students compare the models to videos and other types of multi-media content, but they learn actively and practically”, she adds.

Workshops using 3D printed bones at Victoria University.

Better learning experience translated into better pass rate. It rose from 89 to 99 percent. “That’s huge” says Wilkie.

Conclusions

The team wants to use Zortrax 3D printers for future projects, especially in anatomy courses. Leg bones are to be 3D printed in the near future in the same way the university 3D printed upper limbs. Facts Victoria University wants to 3D print human leg bone models for anatomy courses. Next in line are STEM subjects, especially engineering. Educators at Victoria University want to expand their 3D printing capabilities. “But it doesn’t end there. The success with osteopathy got other academics interested in what we can do. We’re looking at STEM, particularly at engineering courses”, says Wilkie. So far, her team 3D printed measuring devices, cars, and other vehicles. “Anatomy will remain the field where 3D printed educational aids have the most profound impact. It’s such a hard subject to learn. We just need to get more 3D printers”, she concludes.

Victoria University students working with 3D printed bones.