Can we fix it ASAP – 3D printed parts in engineering and manufacturing

At present, the costs of repairing various kinds of equipment are very high. The use of 3D printers and 3D printed parts can change this and allow the production of replacement parts for the majority of pieces of equipment to be much easier and cheaper. 3D printed parts are the future of automotive and engineering industry. Businesses will be the first to benefit from such change.

Are a 3D printed parts a future of manufacturing?

It is widely known that modern equipment is very delicate. It quite often happens that a small component failure can disrupt the operation of an entire production facility. In such a situation, it is necessary to order an appropriate component at a usually high price and then install it. The whole process can take several days or even weeks. During this period, a factory or a production plant does not use its full production capacity.

Image: 3d printed car engine prototypes. Prototypes Fueled by Cutting-Edge Technology

Broken elements are usually made of plastic. On one hand, this is the reason why they can be easily damaged; but on the other hand, the cost of producing such a replacement part is very low. Unfortunately, production plant owners are not aware of this as replacement parts are sold with a huge margin. Hence, why more and more companies decide to produce replacement parts instead of buying them.

Future is now!

Only a few years ago it would have been very difficult if not impossible. However, nowadays the situation is changing thanks to 3D printing. You only have to have a 3D printer and a file containing a three-dimensional model of the damaged part. It can be purchased from the manufacturer of the equipment being repaired or designed with the use of appropriate software. Next it must be converted to the format which a 3D printer can read. Then you should save the model on an SD card, insert the SD card into the printer, select the file, press the “Print” button and now you can watch the “magic at work”.

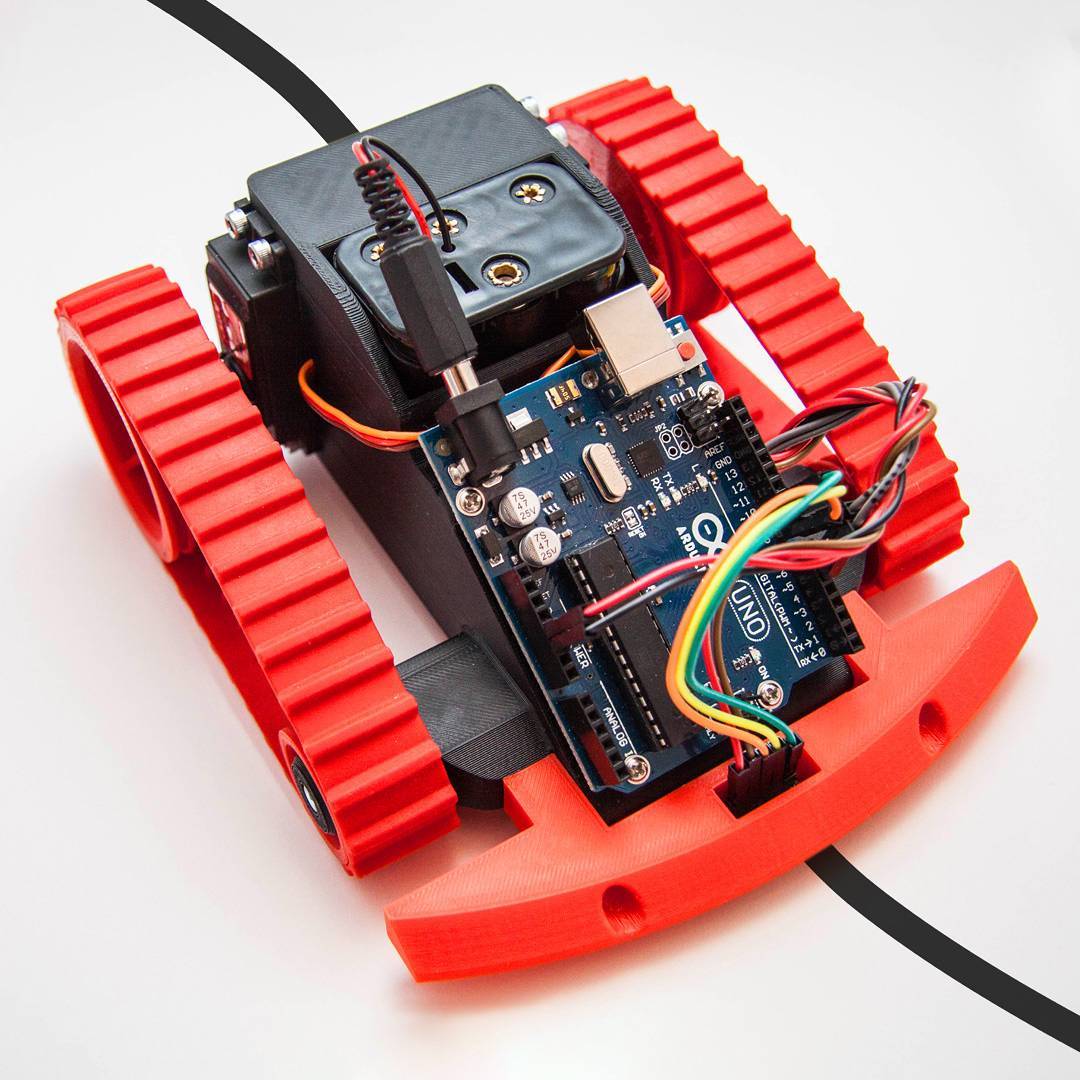

Image: 3d printed parts for robots

The Polish Military Aircraft Maintenance and Servicing Plant No. 2 uses Zortrax M200 printers at the initial stage of designing and testing aircraft replacement parts. Consequently, if this solution has been successfully applied in the aircraft sector, it surely is good enough to build any replacement part for practically any kind of equipment. Furthermore, there are plans to use 3D print technology in space. The expensive and lengthy transport of successive replacement parts into the orbit or to other planets will no longer be necessary. Astronauts will be able to simply use 3d printed parts any necessary components as they orbit the earth.

Improve manufacturing processes with 3D printed parts

There are also more down-to-earth examples of 3D technology applications, for example, Bosch uses Zortrax M200 printers. Even though the solution was introduced in only one production plant, it has already generated savings of approx. EUR 80,000. This was possible as a result of printing replacement parts on-site, among other things.

Earlier the company was forced to pay EUR 450 for a simple component. Now it can manufacture it itself for less than EUR 1. Besides, 3D printers make it possible to build simple tools dedicated to solve numerous problems which facilitate work and save employees’ time. A good example of such equipment is a device clipping connectors to PCBs, or a device making it easier to unplug USB cables.

Not only high-tech gadget?

3D printers are not only high-tech gadgets but they are also tools which improve manufacturing processes and the cost-effectiveness of any production plant. That is why such solutions will be used by an ever-increasing number of companies and home users who will soon discover the great potential of this technology.