Guide to Dealing with 3D Printed Rafts that Won’t Come Off

Summary

- Rafts fuse with models because the filament gets overheated.

- To avoid this, keep the temperature in the room between between 23 and 28 °C.

- Malfunctioning extruder fans, a heater & thermocouple, extruder printed circuit board (PCB), extruder cable, and motherboard can be also to blame.

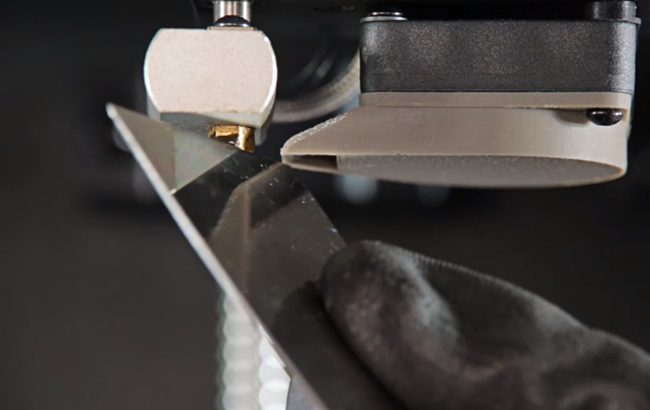

Most FDM 3D printers can print models on the raft, a flat structure made with the first few layers of filament to increase adhesion and dimensional accuracy. More intricate models also need additional support structures to keep overhangs from falling. In a single-extrusion 3D printer, the raft and support structures need to be manually removed from the model once the 3D printing is done. In most cases it’s a very simple step. But sometimes the raft and supports become so firmly attached to the model that it’s almost impossible to split them up. Here’s why it happens and how to deal with it.

Stay Cool

The issue is usually caused by material’s overheating. If ambient temperature in the room exceeds 28°C, the extruded material does not have enough time to cool down. Facts Ambient temperature should be kept below 28°C. Proper platform calibration is very important. Layers bond too heavily when the material is overheated. As a result, the individual layers of the model become viscous, heavily fixed to each other and make the raft and support removal impossible. The next possible reason is platform calibration. If the distance between the nozzle and the platform has not been properly set, which means the platform and the nozzle are too close to each other, the material does not have enough space to be deposited. Thus, the material gets overheated and respective layers of the model bond with each other too much. Another probable reason is a clogged nozzle or hotend. When there are material residues in one of these parts, the extruded material gets overheated and causes the model’s layers to fuse with each other.

Another probable reason is a clogged nozzle or hotend. When there are material residues in one of these parts, the extruded material gets overheated and causes the model’s layers to fuse with each other.

Hardware Issues

A simple part-malfunction can make the raft and support firmly bond with the model. The list of parts responsible for proper model-cooling includes: extruder fans,Facts Resistance on the heater exceeding 16 ohm can cause material overheating. Malfunctioning fans cannot provide proper material cooling. Replacement of the extruder’s printed circuit board or the motherboard is the last resort. the heater&thermocouple, extruder printed circuit board (PCB), extruder cable, and motherboard. When the extruder lower fan is not in a good condition, for example, its blades spin too slow or do not spin at all, the model is not accurately cooled down, and the raft and support structures are difficult to remove. Bu there are more possible reasons. If resistance on the heater exceeds 16 ohm, the heater&thermocouple will start to overheat the material. Additionally, when one of the extruder cable’s paths is broken, the cable can’t transmit appropriate information about the temperature from the motherboard to the PCB. Same thing happens when either the PCB the motherboard’s got damaged. If that’s the case, a proper extrusion temperature for a particular material is exceeded and the model gets overheated.

Additionally, when one of the extruder cable’s paths is broken, the cable can’t transmit appropriate information about the temperature from the motherboard to the PCB. Same thing happens when either the PCB the motherboard’s got damaged. If that’s the case, a proper extrusion temperature for a particular material is exceeded and the model gets overheated.

Fix it Yourself

To prevent your models from overheating, it is important to provide suitable printing conditions by ensuring an ambient temperature stays in between 23 to 28 °C. Facts If side covers are used, try to 3D print without them. Overheating can be caused by a clogged nozzle. Nozzles clogged with ABS can be cleaned with acetone. If you have already encountered the problem and your printer is equipped with side covers, it’s best to remove them. Moreover, remember the platform should be well-calibrated. If you cannot reach proper calibration values, follow the platform maintenance procedure available at our Support Center that will allow you to remove material residues causing bulges under the perforated plate.

If you use ABS-based filaments, try cleaning the nozzle with acetone to get rid of material leftovers. In case you have used other filaments, it is recommended to install a new nozzle. If neither cleaning the nozzle or replacing it has helped, you should get a new hotend. Further, if any of the above-mentioned suggestions has not solved the problem, you need to consider replacing the heater&thermocouple together with the extruder PCB, then the extruder cable, and, as a last resort, the motherboard. That’s how you can deal with 3D printed rafts and supports that won’t come off.